When it comes to maximizing the lifespan of your power tools, choosing quality tools is the first step. Investing in well-made, durable tools pays off in the long run. High-quality brands often use better materials and construction techniques, ensuring that their products can withstand the rigors of heavy use. While it might be tempting to opt for cheaper options, remember that a lower initial cost can lead to higher expenses down the line due to repairs or replacements.

Another benefit of investing in quality tools is the performance they deliver. High-end power tools are designed for precision and efficiency, making your projects quicker and more enjoyable. You'll find that using tools that operate smoothly reduces the strain on both you and the equipment, resulting in less wear and tear over time. This efficiency is especially crucial for professionals or DIY enthusiasts who tackle demanding tasks regularly.

Additionally, reputable manufacturers often provide better customer support and warranties. When you choose tools from trusted brands, you can feel assured that help is just a call away if something goes wrong. Many offer extensive warranties that cover repairs or replacement, which can save you money and frustration in the event of a malfunction. This level of backing is typically lacking in lower-quality options.

Ultimately, it’s not just about the cost of the tool; it’s about the value it brings over time. By choosing quality tools, you’re making an investment in your craft that can lead to more successful projects and a longer lifespan for your equipment. Opt for tools that are built to last, and you'll be taking a significant step toward ensuring that your power tools serve you well for years to come.

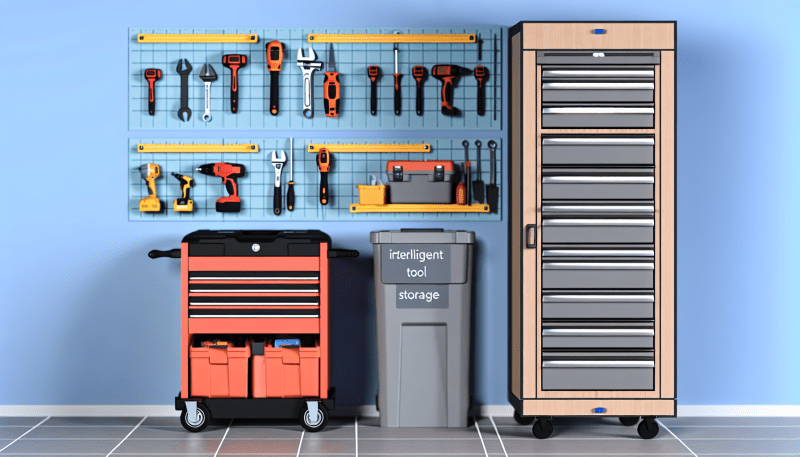

Store Your Tools Properly

Properly storing your power tools is key to extending their lifespan. Many users overlook this crucial step, assuming that just placing them on a shelf or in a toolbox is enough. However, taking a few extra precautions can prevent damage and ensure your tools are always ready for your next project.

First, consider investing in a dedicated storage system. Toolboxes or pegboards can help keep your power tools organized and easily accessible. This not only protects them from potential damage but also reduces the time spent searching for the right tool. Make sure to store them in a dry, cool place to avoid rust and corrosion, especially for tools that have metal components.

Another important tip is to clean your tools before putting them away. Dirt, dust, or debris can build up and cause problems over time. A simple wipe-down with a cloth and some mild soap can do wonders. For power tools, ensure that any moving parts or blades are free from debris, as this can significantly affect their performance on your next use.

Finally, don’t forget to check your power tools regularly while in storage. Periodic maintenance can help spot any issues early on, preventing costly repairs down the line. A quick inspection for signs of rust or wear can keep your tools functioning well and extend their life dramatically.

Regular Maintenance Keeps Tools Efficient

Regular maintenance is essential for keeping your power tools running smoothly and efficiently. Just like any other piece of equipment, tools can wear down over time due to regular use. A little bit of care goes a long way in ensuring that your tools remain dependable and effective, making your projects easier and more enjoyable.

Start by cleaning your tools after each use. Dust, debris, and leftover materials can accumulate and affect performance. Wipe down surfaces, clean filters, and ensure that blades or bits are free from any buildup. Not only does this help in maintaining the efficiency of the tool, but it also prevents rust and corrosion, which can lead to expensive repairs or replacements.

In addition to cleaning, regularly check for any loose or damaged parts. Tighten screws, replace worn-out components, and lubricate moving parts as recommended by the manufacturer. This proactive approach can prevent minor issues from escalating into major problems. Scheduling maintenance checks periodically ensures that you’re aware of any potential threats to your tools' performance.

Lastly, always follow the manufacturer's guidelines for maintenance. Each tool may have specific requirements to keep it in top shape. By adhering to these recommendations, you not only enhance the lifespan of your tools but also ensure that they operate safely, reducing the risk of accidents or injuries while you work. Regular maintenance is a simple yet effective way to maximize the functionality and durability of your power tools.

Follow Safety Practices for Durability

When it comes to maximizing the lifespan of your power tools, following basic safety practices can make a world of difference. One of the simplest ways to ensure durability is to always use the right tool for the job. Using a tool beyond its intended purpose can lead to unnecessary wear and tear, resulting in quicker breakdowns. Take a little time to understand what each tool is designed for; it will save you both time and money in the long run.

Another essential safety practice is to keep your tools clean and well-maintained. After each use, take a few moments to wipe down your tools and remove any debris. Dust, grime, and residue can cause parts to wear out faster. Furthermore, make it a habit to regularly inspect your equipment for any signs of damage. Noticing small issues early on can prevent them from developing into larger problems, ensuring your tools remain in good working condition.

Storing your power tools properly is also crucial for maintaining their durability. Keep them in a dry, cool place away from extreme temperatures or humidity. Use a toolbox or designated storage area to avoid clutter and protect your tools from accidental damage. If your tools come with protective cases or covers, utilize them! Proper storage helps keep your tools safe and extends their life.

Lastly, prioritize safety gear while using power tools. Wearing appropriate personal protective equipment (PPE) not only keeps you safe, but it also helps maintain the integrity of your tools. For instance, safety goggles can prevent debris from entering the tool's mechanism, while gloves can protect your hands from injury and help you keep a better grip. By incorporating these safety practices into your routine, you can ensure that your power tools are not only safe to use but also built to last.